Front runner

for dip coater

Since 1997, SDI Corporation has been advancing its dip coater business by manufacturing and selling "fully automatic dip coaters (dip coating equipment)" for printed circuit board manufacturing. Currently, we pride ourselves on having the industry's number one range of models, developing multi-functional devices that respond to customer demands, and handling the application of dip coaters in various fields. Our primary focus is on creating devices that make our customers genuinely glad they purchased an SDI dip coater (dipping equipment), feeling that it has enhanced their research outcomes.

-

Products

We focus on offering the industry's top variety of models, creating multifunctional devices that meet our customers' requests, and working on the application of dip coaters across multiple fields. Our main goal is to ensure that purchasing an SDI dip coater (dipping equipment) is seen as a truly beneficial decision by our customers, one that significantly enhances their research outcomes.

-

Contract Coating

We accept contract coating services exclusively for "fluorine-based anti-fouling coatings" and "UV-curable hard coatings." This eliminates the need for equipment purchases, helping to reduce initial costs. We offer a comprehensive service that includes incoming inspection, coating in a newly installed cleanroom environment, pre-shipment inspection, packaging, and shipping.

Features

of the SDI Dip Coater

We provide a My Dip Coater

(dip coating device) that meets your needs

The dip method of the dip coater involves dipping into the dip coating solution and then lifting out, which is used for coating applications. As such, it is characterized by its ability to form a uniform thin film with minimal loss of the coating solution, regardless of the shape of the target. At SDI, we offer a diverse lineup ranging from ultra-low speed specifications to mass production equipment. Basically, we provide customized specifications and are committed to providing original equipment. The product lineup covers a wide range of processing speeds from 1 nm/sec to 200 mm/sec for the dip coater speed range, enabling uniform thin film formation due to uneven speed and low vibration. In addition, the touch panel system allows easy operation. Of course, it is also compatible with PCs.

Basic Features of the Dip Coater

- Forms a uniform

thin film - Simultaneous coating

on both sides - Independent

of shape - No loss of

coating solution - Simple

maintenance

* Features of our dip coaters (dip coating equipment) vary depending on the model.

Features of the SDI Dip Coater

- Achieves the industry's highest

standard of ultra-low speed specifications

(1 nano meter

per second). - A wide range of

models available - Forms

a uniform

thin film

due to low vibration and

stable lifting speed - It is possible to change

the speed and set the stop time

at any desired

point. - Multiple full and

partial

re-coatings are

possible. - The device is easy to

operate and maintain. - It accommodates

various

customizations. - Compatible with

touchpanels

or PCs. - Stop time of "0"

seconds when

changing speeds. - Smooth changes

in dip

coating speed

are possible.

Accurate proposals from SDI staff

A dip coater

that satisfies you

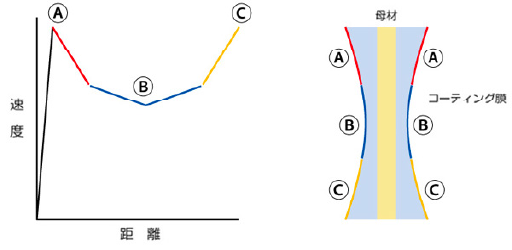

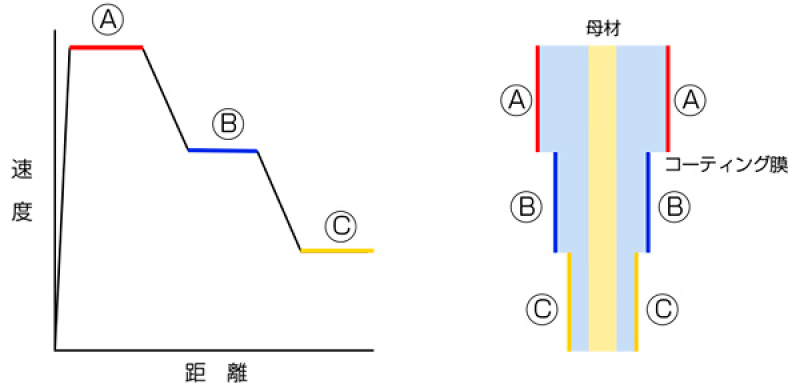

Linear Driving Mode (Applicable model: LD-1304-S2)

A mode of dip coating that linearly changes the speed of the dip coat from a specified position A to position B, creating a smooth change in film thickness.

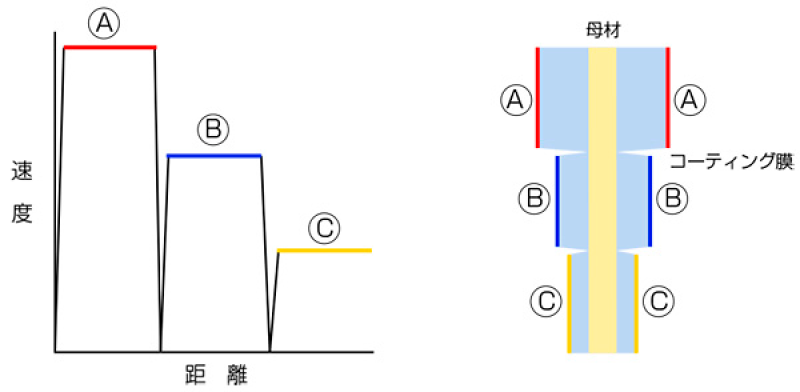

Continuous operation mode (applicable to all models except DT-0001-N1)

Dip coating mode in which the dip coating speed change time is set to "0 sec", i.e., the dip coating speed is changed immediately at the position where the dip coating speed is changed, which can be set arbitrarily.

Standby operation mode (applicable to all models)

Dip coating speed change time can be changed from a minimum of 0.1 sec. to a maximum of 999.9 sec. at the position where the dip coating speed is arbitrarily set to be changed. A mode of dip coating for situations where dripping of the dip coat liquid and impregnation into the dip coating material are required.

Note: The shape of the coating film is merely a reference (image).

The characteristics of the coating liquid may cause significant variation.

Watch SDI's Dip Coater

in Action

Product information

For experiments, research, development, and desktop use

Micro Dip® Coater MD-0408-N1

The optimal dipper coater for ultra-low speed dip coating (dip coating), our No. 1 bestseller.

For small-lot production and release agent coating

N2 purge specification Linear Dipper Coater LD-1811

This device is an apparatus that can dip-coat 10 pieces of 40mm square substrates simultaneously.

Automatic equipment for mass production

Hardcoat Material Coating Machine HC-1004

This machine is a semi-automatic dip coater (dip coating) aimed at automating the washing, dip coating of hardcoat material, hot air drying, and UV curing of polycarbonate plates after injection molding.

Dip coater SA-2203 for photoresist coating

This machine is a dip coater that automatically performs the dip/drying process for the purpose of thin film dip coating of photoresist liquid simultaneously on multiple 4-inch wafers, metal plates, glass, etc.

See What Our Customers Say

You explained the process during the meeting, including your experiences with failures. Thanks to you, we were able to select the optimal equipment for reviewing the facilities. I'm also grateful that you accepted changes to the program.

Chemical Manufacturer (Listed Company)

From proposing manufacturing processes to selecting coating liquids, lending test equipment, and cooperating within a limited budget and timeline for the subsidy project.

Injection Molding Manufacturer

Contact

Contract Coating

We provide contract coating services using a dip coater in a clean room. We are also proud of the strict standards of inspection we have developed over the years.

We provide consistent service from the prototype stage to incoming inspection, pre-shipment inspection, packaging, and shipping. Furthermore, since there is no need to purchase the device, it is possible to reduce the initial costs. We can also recommend coating liquids. Please feel free to contact us.

SDI Corporation

Customer Service Center

As a designer and manufacturer, we are able to customize our products with the utmost care and attention to detail.

If you have any requests or questions, please feel free to contact us.

-

Inquiries by Phone

Business hours: 9:00 to 17:00

* Excluding Saturdays, Sundays, public holidays,

and substitute holidays -

Inquiries via facsimile

075-323-0237

Business hours: 24-Hour Reception

Japanease

Japanease English

English

Contact us by email

Contact us by email